Written by Meghan Kaiserman, Strategic Marketing Director

Abstract

To meet net zero CO2 emission goals, the building sector needs to modernize its communication infrastructure. This article shows how single-pair Ethernet, specifically 10BASE-T1L, enables the easy retrofitting of buildings using legacy links like RS-485 to improve digitization, enable automation, improve security, and substantially lower energy consumption to achieve greater sustainability.

Introduction

To address climate change and sustainability, over 90 countries are actively developing net zero CO2 emission policies. In short, net zero is achieved when human-based CO2 emissions are both reduced and counterbalanced through other activities.

A fundamental factor in reaching net zero is the reduction of CO2 emissions across all industries. However, according to the International Energy Association (IEA), the building sector is not on track to meet global 2050 net zero CO2 emission goals. Specifically, 2030 goals target 35% less energy consumption per square meter compared to 2021.1 As buildings account for 30% of global energy consumption today, there is concern that emission goals will not be met unless the industry takes specific action to digitize systems and implement automation. Further complicating the challenge is that to implement effective automation, more real-time data capture is needed at a level that exceeds the current throughput capacity and responsiveness of legacy RS-485-based infrastructure. In addition, connecting devices and building systems to the network exposes them to cyberattacks, requiring advanced security beyond the current capabilities of these legacy networks.

This article explores how single-pair Ethernet can help the building industry meet net zero goals while supporting AI-based automation in a secure and cost-effective manner. Single-pair Ethernet enables long-reach connectivity to the edge for both greenfield and retrofit installations, making it a critical tool for seamless data transfer between IT and OT domains.

Energy Savings Through Digitalization

The IEA 2030 Net Zero plan3 requires a ~15% reduction in emissions by reducing demand through techniques like behavioral changes and digitalization. While teaching people how to conserve energy can be effective, IEA case studies4 point to automation rather than behavior change as having the most potential for energy reduction.

Increasing digitalization of commercial buildings will enable operators to not only measure operational improvements but also provide the foundation for operational automation. With access to the right sensor data and control capabilities, it is possible to optimize the operation of buildings to reduce energy consumption while best serving the people within.

For example, the need to improve indoor air quality places additional demands on building operations. New regulations such as ANSI/ASHRAE 62.1 require the intake of more outdoor air, and additional amounts2 may be required to ensure best practices for health and hygiene. These ventilation standards will result in increased energy consumption, meaning energy demand will need to be further reduced. To achieve optimal operation, the many HVAC systems within a building need to be able to work together to avoid having the systems work at cross purposes.

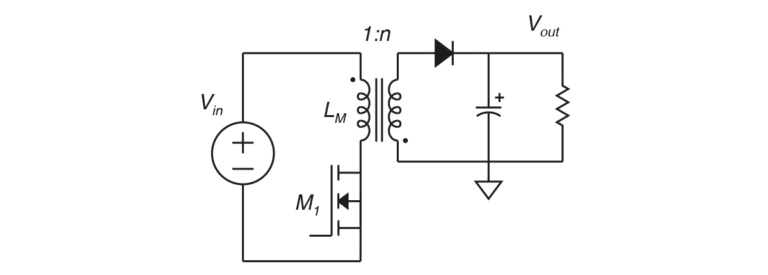

Converging operations of disparate HVAC, lighting, fire, and access control systems requires access to the right data and controls. These allow AI and machine learning (ML) optimization to determine the ideal use of light, heating, or cooling based on people’s current and planned activity. They also allow control of airflow to help ensure proper indoor air quality while balancing energy consumption.

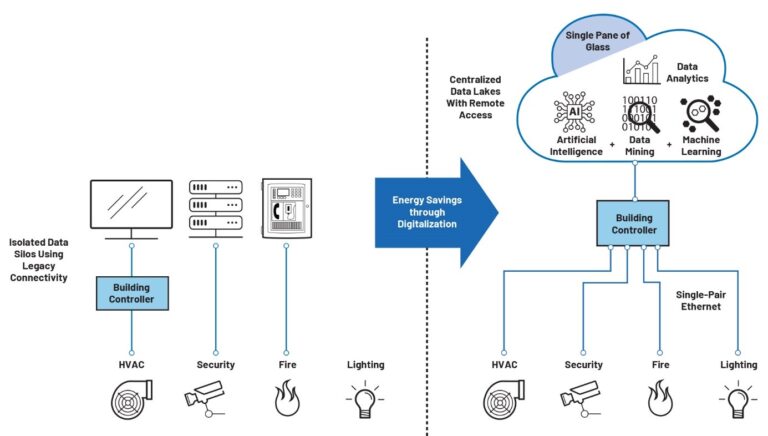

However, it is hard to converge data from multiple systems with separate vendors maintaining separate databases, leading to data siloes. According to the IEA group working on data sharing guidelines5 for buildings and HVAC systems, the challenge then is to bring diverse data sources together in a single pane of glass, so that trends can be compared, and analytics applied, to yield new insights, as shown in Figure 1.

Modernizing the Communications Infrastructure

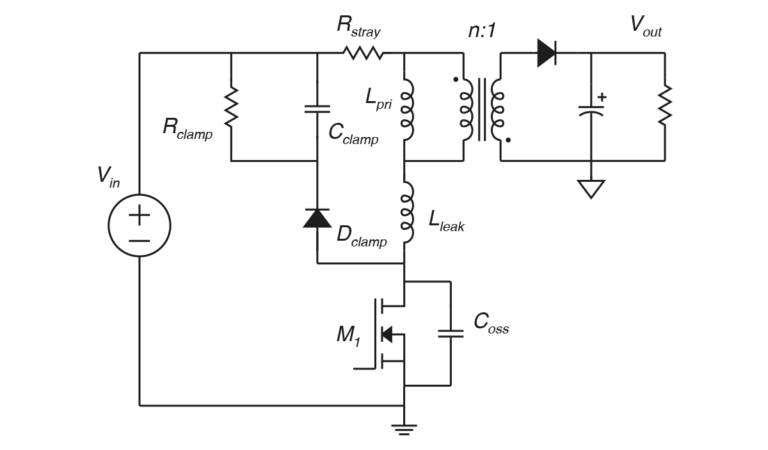

Key to merging the many different data sources within a building is the measurement and connectivity infrastructure being used. Traditionally, sensors and controls in commercial buildings have been connected through wired serial communication links using RS-485 transceivers and protocols like BACnet™, Modbus, and LonWorks.6

RS-485, however, is a legacy interface that is limited in both throughput and security. For example, the maximum baud rate for BACnet MS/TP, a common building automation protocol, running on an RS-485 physical layer is 115.2 kbps.10 In addition, legacy communication protocols like BACnet and Modbus were designed for closed networks and lacked built-in encryption and authentication capabilities. This creates a large cybersecurity threat as these devices are connected to the internet through gateways to IT infrastructure.

Single-pair Ethernet, specifically 10BASE-T1L, is an exciting new communication method ratified on November 2019, IEEE 802.3cg, which is now being deployed in buildings.9 Wired serial link cable used for RS-485 runs can be reused with 10BASE-T1L Ethernet data running over it. Thus, existing infrastructure can be adapted to single-pair Ethernet. This has many benefits:

- Nodes can now support higher bandwidths of up to 10 Mbps.

- Nodes are IP addressable, simplifying the management of devices.

- Reach increases to 1 km, which is enough to support the maximum lengths used for existing RS-485 cabling runs. This is a marked improvement over standard 10 Mbps/100 Mbps Ethernet’s limit of just 100 m.11

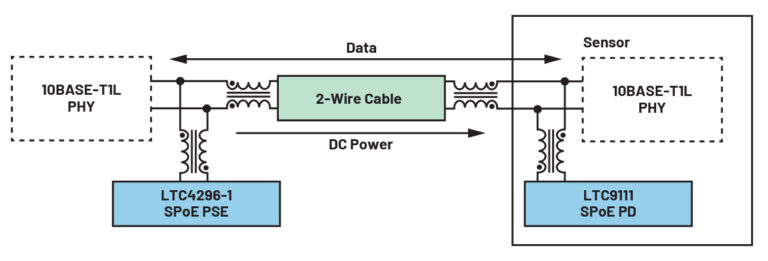

- IEEE 802.3cg specifies Class 15 and allows up to 52 W of power to be sent over single twisted pair cable along with 10BASE-T1L data. With the recently released LTC4296-1 power over Ethernet (PoE) controller, systems can deliver power to a wide range of end devices. Note that due to variations in cable quality, power delivery is recommended for new installs only.

As a first step in the digitalization journey, building controllers using standard 10 Mbps/100 Mbps Ethernet have been deployed, communicating with Ethernet-based versions of these legacy protocols, called BACnet/IP and Modbus TCP/IP.6 BACnet/IP devices use the same data objects as BACnet MS/TP legacy devices, so it is easy to implement a system with both types of devices. Ethernet-connected installs with IP-based protocols like BACnet/IP and Modbus TCP/IP that support modern cybersecurity measures are on the rise.12 BACnet has about 60% market share7 worldwide and about 80% of new installs are using wired RS-485-based serial communications. The Building Services Research and Information Association (BSRIA) estimated that in 2019, 5% of HVAC sensors were wireless with lower connection reliability and the need for batteries limiting where this can be adopted.8

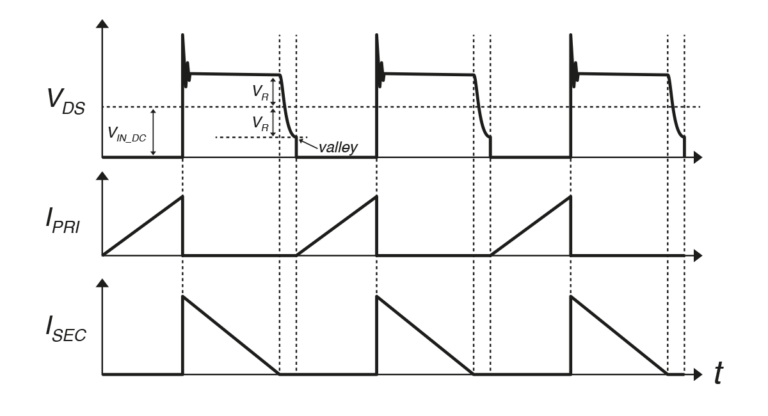

Improved Communications

Heating and cooling systems have multiple components that need to exchange information to achieve the temperature set point, including thermostats, controllers, air handling units, and variable air volume units. Speeding up the frequency of communication from common serial baud rates of 9.6 kbps to 115.2 kbps to an Ethernet bandwidth of 10 Mbps means the data throughput of the system has increased substantially. There are several important benefits that come with such high speed IP-based communications.

Figure 1. Converging systems allow data visualization through a single pane of glass, which enables energy savings when used alongside automation and AI/ML.

Analytics, not samples: The slow data rates of legacy communication meant building managers had to prioritize what data they collected and sample the data they did collect. With single-pair Ethernet, managers can stop worrying about serial communication sampling rates and focus on developing the wide range of advanced analytics they can now perform with the additional data that can be collected from the system.14

Energy savings: Additional data enables greater energy savings through faster control loops or computationally intensive energy optimizations using models and real-time sensor inputs.

Converged data/elimination of data siloes: Legacy-wired serial communications require a gateway to convert data from edge devices into Ethernet-based packets before passing them to the cloud. Upgrading wired serial communication links to single-pair Ethernet, 10BASE-T1L, allows these gateways to be eliminated while reusing the existing cabling. This avoids data siloes, reduces failure points, eliminates the cost of gateways, and drives down overall latency.

Real-time responsiveness: Communication protocols and software running on gateways slow down response time to the order of seconds, while building automation applications such as IO monitoring may require 100 millisecond or lower latency.13 The higher throughput of single-pair Ethernet combined with the elimination of gateways means faster throughput so systems can respond in real-time.

Secure Communication

Memoori12, a leader in smart buildings research, cites that the lack of effective cyber cover is rapidly becoming the leading barrier to smart building adoption moving forward.

One of the biggest challenges faced with building digitalization is converging the IT and OT domains. It is possible to retrofit security into legacy RS-485-based field bus OT networks by upgrading to protocols like BACnet/SC, but this is costly, time-consuming, and can easily miss vulnerabilities in the existing system. Effective security is critical as building automation systems received the most cyberattacks among all industrial control systems, higher than oil and gas, energy, and automotive manufacturing in a 2020 study by Kaspersky.15

To secure communications, the legacy wired serial communication protocol BACnet has been adapted to BACnet/SC12, which supports secure communications on a wired serial link allowing encryption. However, all BACnet devices on the network need to be upgraded simultaneously to take full advantage of these new capabilities. Existing equipment using legacy BACnet will need to be redesigned and serviced to add the additional cryptography functions required for BACnet/SC. Single-pair Ethernet, specifically 10BASE-T1L, allows an edge node that had been connected using wired, insecure serial communications like BACnet to be upgraded and connected using BACnet/IP protocol running Ethernet-based security. Importantly, this new and improved security posture is achieved without running new, costly Ethernet cables along existing signal paths.

By upgrading devices on OT networks to run secure Ethernet-based protocols, much of the risk associated with cyberattacks can be mitigated. Single-pair Ethernet, 10BASE-T1L, has the promise of enabling the transition from insecure legacy communication to secure Ethernet-based communications with one generation of hardware upgrades while reusing existing wiring infrastructure.

Single-pair Ethernet, 10BASE-T1L, is an important technology that brings IP connectivity to the edge, improving security, reusing wiring, converging IT and OT networks, and even delivering power. With significantly higher throughput, elimination of gateways, and advanced security, single-pair Ethernet will help the building industry achieve the IEA Net Zero 2030 goal of reducing emissions by 15%. Modernizing the communication infrastructure of buildings will provide access to a tremendous amount of real-time data within a building while eliminating data siloes and enabling a single pane of glass approach to management. In addition to allowing faster control loop closure for conventional control schemes and supporting artificial intelligence and ML optimizations, managers will be able to generate actionable insights that result in substantial energy savings.

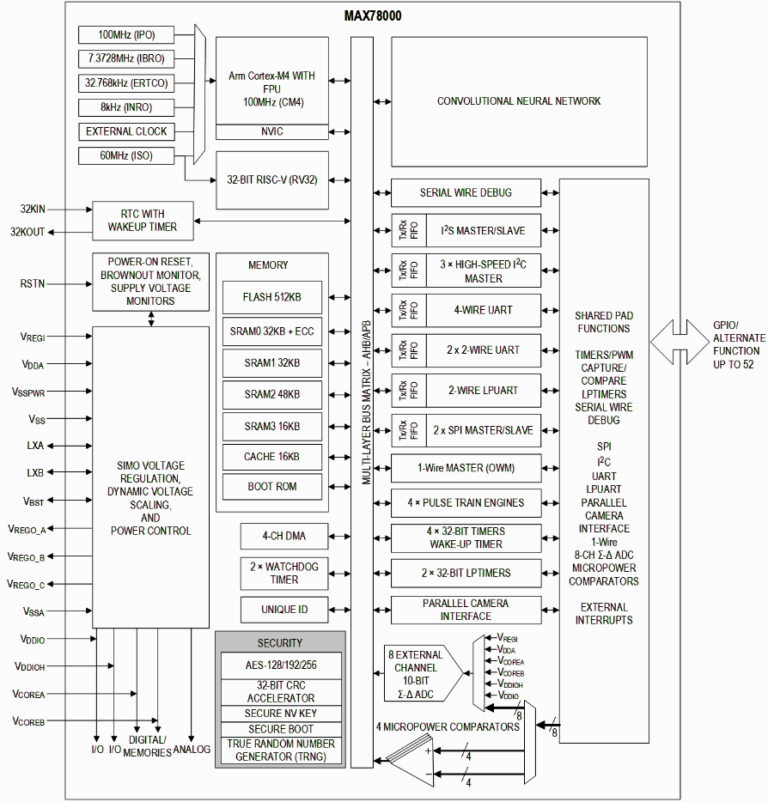

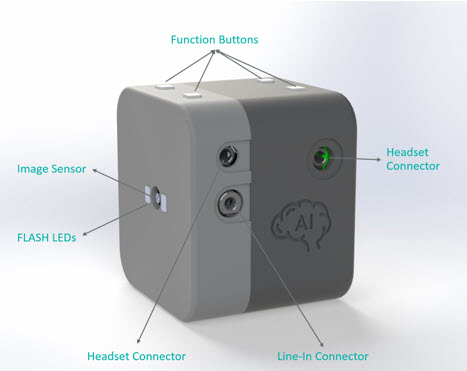

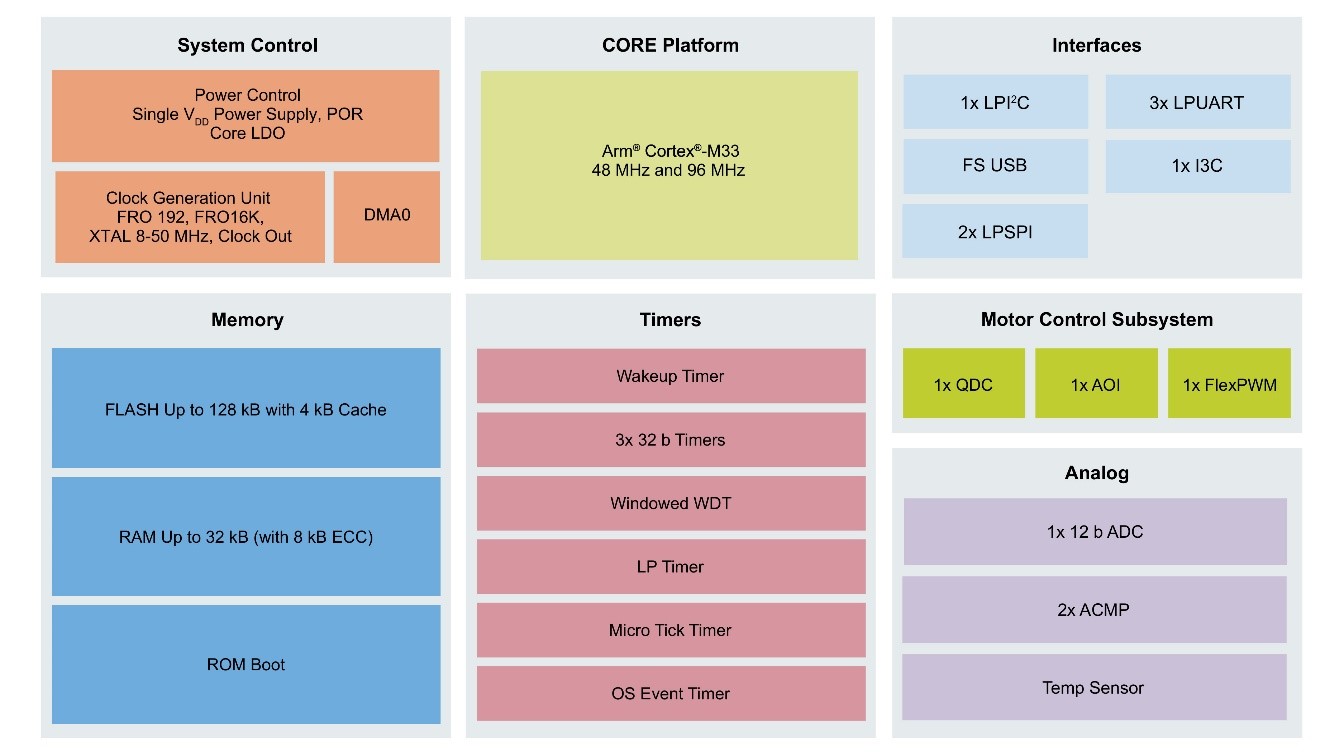

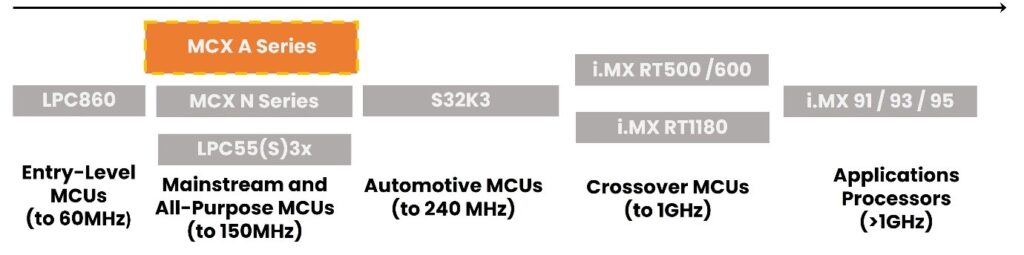

Analog Devices has a team focused on the sustainable buildings market and is a leader in technologies enabling digital transformation such as single-pair Ethernet (10BASE-T1L), security and intelligent IOs, as well as isolation and wired RS-485 transceivers for legacy systems. Analog Devices has several released single-pair Ethernet products enabling point-to-point (ADIN1100, ADIN1110) as well as line-and-ring architectures (ADIN2111).16 For single-pair power over Ethernet, please see the LTC4296-1 on the power sourcing side and LTC9111 on the device side.

References

1 “Buildings.” International Energy Association.

2 “New Ventilation Design Criteria for Energy Sustainability and Indoor Air Quality in a Post COVID-19 Scenario.” Renewable and Sustainable Energy Reviews, Vol. 182, 2023.

3 Net Zero by 2050—A Roadmap for the Global Energy Sector. International Energy Association, 2021.

4 Energy Efficiency 2021. International Energy Association, 2021.

5 IEA Annex 81 Activity A1—A Data Sharing Guideline for Buildings and HVAC Systems. International Energy Association, 2023.

6 The Ultimate Guide to Building Automation Protocols. Smart Buildings Academy, 2020.

7 “Research Study Indicates BACnet Global Market Share over 60%.” BACnet International, 2018.

8 “A New Detailed US Field Device Study Is Released.” BSRIA, 2020.

9 “Single Pair Ethernet on Its Way into the Smart Building.” Smart Buildings Technology, 2020.

10 Improving BACnet®. BACnet, 2020.

11 “How to Cost-Effectively Network Sensors for Building Management Systems.” DigiKey, 2023.

12 “Cyber Security in Smart Commercial Buildings 2022 to 2027.” Memoori, 2022.

13 “Industry 4.0 for Energy Productivity.” RACE for 2030, 2021.

14 “How IP Controls Are Changing Building Automation Controls.” ControlTrends, February 2022.

15 “Threat Landscape for Industrial Automation Systems.” Kaspersky, March 2021.

16 “Building Automation Controllers and Networks.” Analog Devices, Inc.

About the Author

Meghan Kaiserman is the strategic marketing director for sustainable buildings at Analog Devices and is focused on digitalization technologies including intelligent IO, single-pair Ethernet, and security. Meghan has over 18 years of service at Analog Devices and previously held roles in applications and systems engineering. She has developed products for the industrial market ranging from precision analog to energy measurement and Industrial Ethernet. Meghan received a B.S.E.E. from the Cooper Union for the Advancement of Science and Art in New York City.

Disclaimer: This article has been published with explicit permission from Analog Devices Inc. (ADI), who has granted Excelpoint the rights to produce and share this content on our platform. All information, insights, and viewpoints are provided in collaboration with ADI, ensuring authenticity and accuracy. No part of this article may be reproduced or utilized in any form or by any means without prior written consent from ADI and Excelpoint.