Media

- Media

- Analog Devices: New Power Supply Concepts Needed for Intelligent Edge Sensors

Analog Devices: New Power Supply Concepts Needed for Intelligent Edge Sensors

Written by Frederik Dostal, Power Management Expert

Question

The Intelligent Edge is spreading across the industry, replacing heritage edge sensors and actuators. Can the Intelligent Edge use common heritage power supplies?

Answer

In some cases, yes, but in most cases, no! Adapted, more advanced power supplies need to be designed.

Abstract

This article introduces different examples of the implementation of Intelligent Edge sensors and how power management solutions are selected and adapted to provide the best solution. This article will explore some of these sensor solutions available today.

Introduction

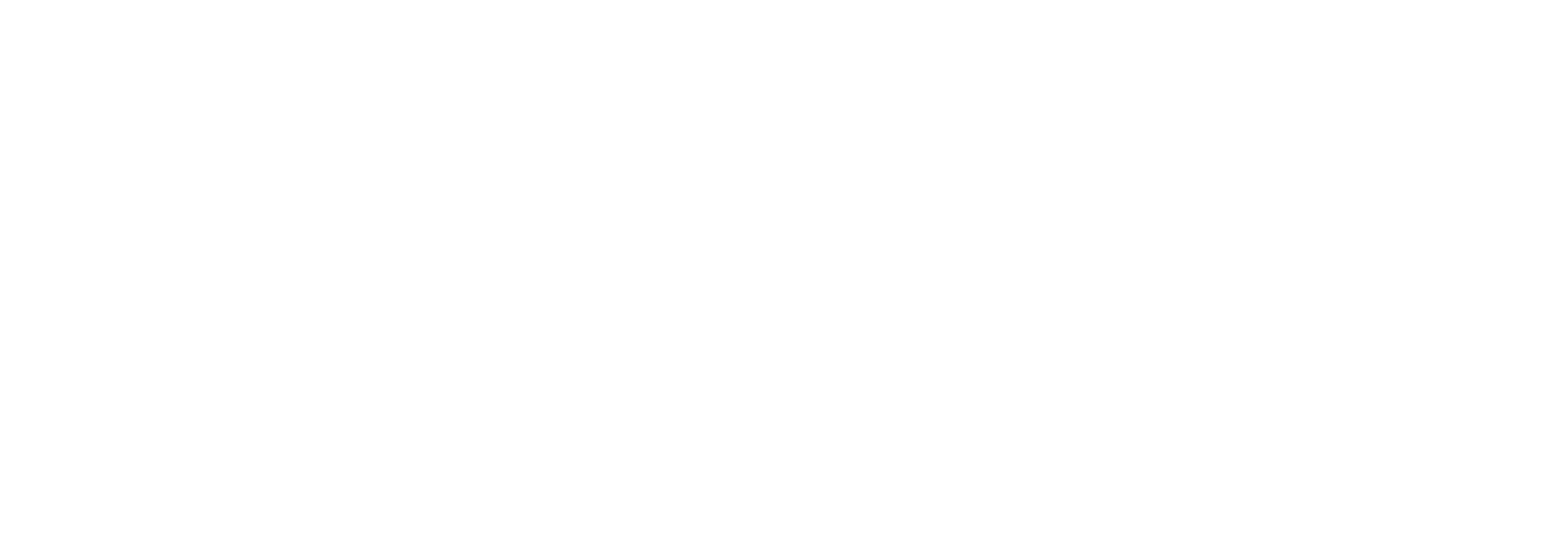

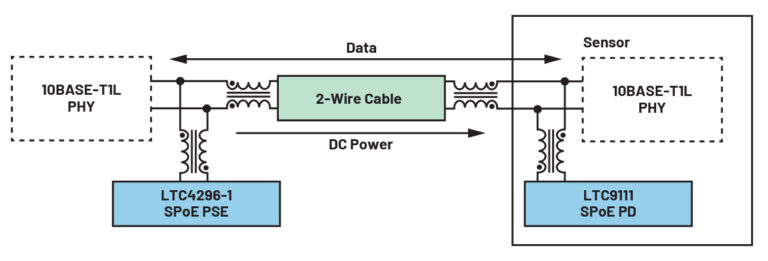

The field of power supplies for industrial sensors is currently ripe with innovations and rife with challenges. Implementation of an Intelligent Edge requires intelligent data preparation. This requires innovations in power supplies. In some cases, sensors at the Intelligent Edge need to be powered by a single twisted pair cable, which a single-pair power over Ethernet (SPoE) solution can provide. In other applications, a nanopower solution helps to save energy to achieve longer run times with a battery at the sensor side. Furthermore, some intelligent sensors require an ultralow noise power supply, so that sensor data is not compromised. Finally, adding sensor intelligence at the edge will require a power supply with a higher power density. This is because new sensors need to fit in an existing form factor.

What Is the Intelligent Edge?

The term Intelligent Edge refers to sensors in industrial systems that can select and process data independently. A lower volume of data is transmitted between the sensors and the central control unit, so data transmission is less challenging. Of course, a microcontroller is needed to process the data supplied by the sensors. A simple example is an optical sensor used for the detection of specific information. For example, it may detect people who accidentally step into an automated manufacturing area, thereby putting themselves in danger. The image data must be processed in such a way that a person can be unequivocally identified so that the machines can be shut down quickly in response. This should serve to prevent injuries. The goal is to have the image data processed at the Intelligent Edge. Only one signal, which is the person detected in the camera’s field of view, is transmitted to the central computer. Transfer of image data to the central computer is done away with. As a result, less transmission bandwidth is required and transmission is simplified.

Nanopower Sensors in Industrial Environments

An example of a low power sensor in an industrial environment in the context of the Intelligent Edge is vibration sensors distributed in a process plant to monitor individual machines.

Figure 1: SPoE supplies up to 52 W via a single 2-wire cable up to 1 km in length.

Figure 2: Nanopower voltage conversion for battery-powered sensors.

Download PDF to Read More

© 2024 Excelpoint Technology Pte. Ltd. All Rights Reserved.