SINGAPORE, 8 November 2023 – As the manufacturing landscape1 undergoes significant shifts towards Industry 4.0, Excelpoint Systems (Pte) Ltd., a trusted leader in providing quality electronics components supports the sector transformation with ADI’s IO-Link® Technology2. This technology offered by Analog Devices, Inc. (ADI) enables manufacturers to achieve peak efficiency and productivity.

ADI’s IO-Link® technology is rapidly shaping the future of the manufacturing sector. Recognized as an integral component of the modern smart factory, it facilitates the transformation of traditional sensors into intelligent, data-driven devices. With this technology, edge devices in manufacturing environments will witness unprecedented levels of intelligence, enhancing their overall capabilities.

The crux of a smart factory lies in its sensors and actuators, making crucial decisions in real-time. With ADI’s IO-Link® technology, traditional sensors are rejuvenated into intelligent entities,” Manufacturers have the opportunity to transform their industrial settings into real-time configurable production zones without the burdensome costs or intricacies of a full revamp.

Moreover, the IO-Link’s innate flexibility reduces common inefficiencies. Where once technicians manually adjusted sensors, a time-consuming and often inefficient process, IO-Link provides seamless adaptability, real-time communication, and a noteworthy decrease in downtimes.

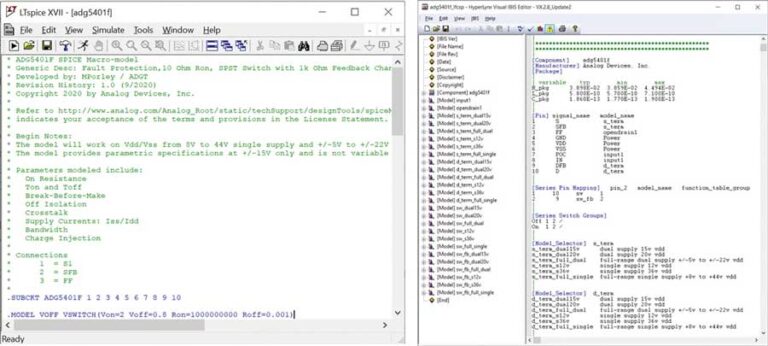

Beyond the IO-Link technology, ADI also offers a suite of high-precision analog converters and signal conditioning tools. These tools, when integrated with IO-Link solutions, provide manufacturers with comprehensive sensor upgrade options tailored to their unique needs.

“The future is here, and it’s digital,” commented said Kenny Ng, Director of Product Marketing, Excelpoint. “ADI’s IO-Link technology is not just a tool but a transformative force. By repurposing existing sensors and equipping them with cutting-edge tech, manufacturers can now have an agile, communicative, and real-time diagnostic-capable process.”

Excelpoint champions the adoption of these innovative smart factory sensor solutions. By bridging the chasm between traditional manufacturing techniques and the digital future, Excelpoint, in collaboration with industry giants like ADI, is poised to guide manufacturers into a new age of efficiency and productivity.

Manufacturers keen to explore and leverage these innovations are encouraged to delve deeper into ADI’s smart factory solutions.

For further details on how Excelpoint can lead your transition to smarter manufacturing, please visit: https://www.excelpoint.com/solutions/smart-factory-sensors/

For media inquiries, please contact:

Ms ONG Hwee Teng

Corporate Communications Manager

Excelpoint Systems (Pte) Ltd.

Tel: +65 6210 6639

About Excelpoint:

Excelpoint Technology Pte Ltd (the “Company”) and its subsidiaries (“Excelpoint” or the “Group”) are one of the leading regional business-to-business (“B2B”) platforms providing quality electronic components, engineering design services and supply chain management to original equipment manufacturers (“OEMs”), original design manufacturers (“ODMs”) and electronics manufacturing services (“EMS”) in the Asia Pacific region. Excelpoint Technology Pte Ltd has been recognised in the Top 25 Global Electronics Distributors and Top Global Distributors lists by EBN (a premier online community for global supply chain professionals) and EPSNews (a US premier news, information and data portal and resource centre for electronics and supply chain industries) respectively.

Excelpoint works closely with its manufacturers to create innovative solutions to complement its customers’ products and solutions. Aimed at improving its customers’ operational efficiency and cost competitiveness, the Group has set up research and development (“R&D”) centres in Singapore, China and Vietnam that are helmed by its dedicated team of professional engineers.

About Analog Devices, Inc.

Analog Devices, Inc. (NASDAQ: ADI) is a global semiconductor leader that bridges the physical and digital worlds to enable breakthroughs at the Intelligent Edge. ADI combines analog, digital, and software technologies into solutions that help drive advancements in digitized factories, mobility, and digital healthcare, combat climate change, and reliably connect humans and the world. With revenue of more than $12 billion in FY22 and approximately 25,000 people globally working alongside 125,000 global customers, ADI ensures today’s innovators stay Ahead of What’s Possible.

Manufacturing landscape1: https://www.excelpoint.com/events/adi-digital-factory-campaign/

ADI’s IO-Link® Technology2: https://www.excelpoint.com/solutions/smart-factory-sensors/